About Us

GD Chargers is a subsidiary of GD Electronic Group, focusing on fast charging and clean energy-related accessories.

Our company has introduced imported automated production equipment, reasonable manufacturing processes, complete testing equipment, and an excellent management team.

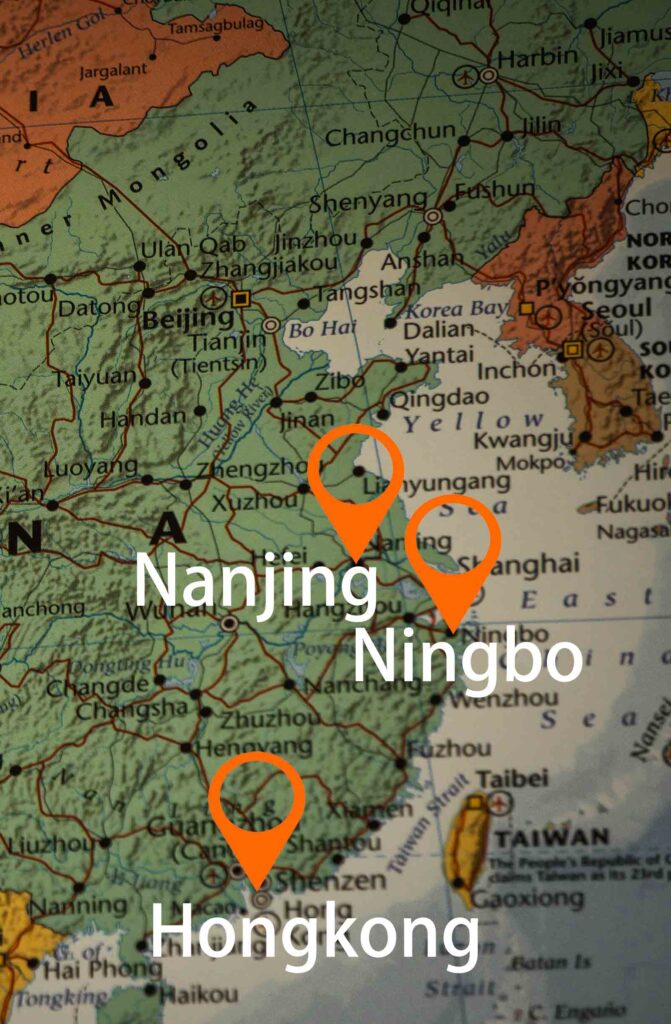

Our company has established long-term stable cooperation with large automobile manufacturers, and its products are mainly sold to the United States, the European Union, North America, the Middle East, Asia, and other regions, winning the favor and praise of customers.

Why choose GD Chargers?

For over two decades, we’ve been on a mission to not only meet customer expectations but to surpass them, crafting long-lasting partnerships built on quality, trust, and integrity. So, why should you choose us for your 2B charging solutions? Let us “charge” you up with some electrifying reasons!

Quality: Our passion is powered by delivering top-notch, high-quality results that exceed your expectations, keeping you and your EV fully charged and satisfied.

Trust: Just like a dependable EV chargers, trust is the foundation of our long-term relationships with clients. Our customers know that they can always rely on us to keep them on the road.

Integrity: We’re committed to doing the right thing in every aspect of our business.

With honesty, forthrightness, and trustworthiness, we ensure that our customer partnerships remain strong and fully charged.

We have passed the management system certification, quality management system certification, environmental management system certification, and IECQ certification. In order to meet the requirements of customers in different regions, we have also conducted corresponding tests and certifications on our products

Here are some production photos showcasing our advanced and comprehensive equipment that can meet the customized needs of different customers.

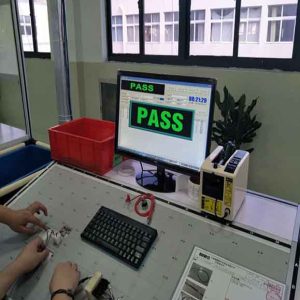

Welcome to our IQC testing area.

IQC (Incoming Quality Control) is a process that involves inspecting and controlling the quality of incoming materials, components, and packaging materials from suppliers to ensure that they meet our company’s quality standards and requirements.

This is an important step in our production and quality management process, as it helps to ensure the quality and reliability of our products and improve customer satisfaction.

Our IQC testing includes inspection of appearance, dimensions, performance, and physical characteristics, and we take corrective action when necessary to ensure consistent quality.

In our material placement area, we have implemented a registration system for incoming and outgoing materials, ensuring an orderly and efficient process. We also have a tracking system in place, making it easy to trace the movement of materials and ensuring accountability throughout the process. This helps us to maintain a high level of organization and efficiency, and ensures that we can easily locate and retrieve materials when needed.

In our semi-finished goods storage area, we have implemented a tracking system that monitors the production process and path of every product. This allows us to trace the origin and progress of each product, ensuring that issues can be quickly identified and resolved. This system helps to ensure that we maintain the highest level of quality for our products, and provides added assurance to our customers that we are committed to delivering reliable and consistent products.

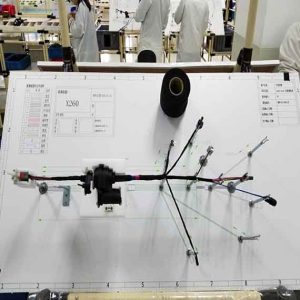

Welcome to our product assembly area!

Our experienced team of over 50 workers is distributed across multiple assembly lines, ensuring that each product is assembled with precision and care.

Our team is trained in the latest assembly techniques and uses advanced tools and equipment to ensure the highest level of quality and efficiency.

We take pride in our work and are dedicated to ensuring that every product that leaves our assembly line meets our rigorous standards for quality and reliability.

We have a range of modern production equipment. These advanced equipment not only improve our production efficiency, but also ensure product consistency and quality stability. We continuously introduce advanced equipment and processes to improve our production efficiency and quality level.

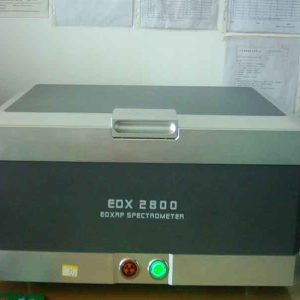

Our testing equipment includes a range of high-precision testing instruments and equipment. We strictly test and inspect each product according to international standards and customer requirements to ensure product quality and reliability. We continuously update and upgrade our testing equipment and technology to meet the changing needs of our customers.

We maintain such strict control over our products, with all of our precision equipment and experienced staff, because everything we do is for you – our valued customers – to ensure that we present you with the very best products possible.

Contact Us

Have a question, suggestion, or feedback?